x

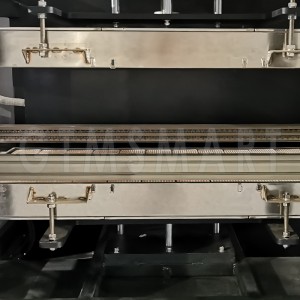

Cylinder Plastic Vacuum Forming Machine HEY05A

Vacuum Forming Machine Specifications

| Model |

HEY05A |

| Working Station |

Forming, Stacking |

| Applicable Material |

PS, PET, PVC, ABS |

| Max. Forming Area (mm2) |

1350*760 |

| Min. Forming Area (mm2) |

700*460 |

| Max. Formed Depth (mm) | 130 |

| Sheet Width (mm) | 490~790 |

| Sheet Thickness (mm) | 0.2~1.2 |

| Accuracy of Sheet Transport (mm) | 0.15 |

| Max. Working Cycle (cycles/minute) | 30 |

| Stroke of Upper/Lower Mold (mm) | 250 |

| Length of Upper/Lower Heater (mm) | 1500 |

| Max. Capacity of Vacuum Pump (m3/h) | 200 |

| Power Supply | 380V/50Hz 3 Phrase 4 Wire |

| Dimension (mm) | 4160*1800*2945 |

| Weight (T) | 4 |

| Heating Power(kw) | 86 |

| Power of Vacuum Pump (kw) | 4.5 |

| Power of Sheet Motor (kw) | 4.5 |

| Total Power(kw) | 100 |

BRAND of COMPONENTS

| PLC | DELTA | |

| Touch Screen | MCGS | |

| Servo Motor | DELTA | |

| Asynchronous Motor | CHEEMING | |

| Frequency Converter | DELIXI | |

| Transducer | OMDHON | |

| Heating Brick | TRIMBLE | |

| AC Contactor | CHNT | |

| Thermo Relay | CHNT | |

| Intermediate Relay | CHNT | |

| Solid-state Relay | CHNT | |

| Solenoid Valve | AirTAC | |

| Air Switch | CHNT | |

| Air Cylinder | AirTAC | |

| Pressure Regulating Valve | AirTAC | |

| Grease Pump | BAOTN | |

Why Choose Us

- Combining advanced features with superior performance, this state-of-the-art machine allows you to easily create high-quality products from a variety of materials including PS, PET, PVC and ABS.

- With our vacuum thermoforming machines, you can achieve excellent precision and efficiency in the forming and stacking process. The Plastic vacuum forming machine features a durable construction that ensures long-lasting performance and reliability. Whether you are a small business or a large manufacturer, this machine is suitable for all production capacities.

- One of the main advantages of vacuum thermoforming machines is their versatility. It is equipped with advanced software that can be easily customized and adjusted for various product sizes and shapes. This flexibility enables you to meet changing market demands.

- Operating a Vacuum Forming Machine is very simple and user-friendly. The intuitive control panel ensures easy navigation and operation, minimizing the learning curve for the operator. Additionally, the machine features quick die changes to reduce downtime and maximize productivity. This means more output in less time, increasing the profitability of your business.

- We understand the importance of excellent customer support, which is why our team of highly skilled technicians are always available to help and support when needed. From installation to maintenance and troubleshooting, we are dedicated to ensuring your uninterrupted operation and overall satisfaction.

Applications

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model: HEY05B

Model: HEY05BServo Vacuum Forming Machine HEY05B

Automatic Vacuum Forming Machine Specifications Model HEY05B Working Station Forming, Stacking Applicable Material PS, PET, PVC, ABS Max. Forming Area (mm2) 1350*760 Min. Formi... -

Model: HEY01

Model: HEY01PLA Degradable Compostable Plastic Lunch Box Plate Bowl Tray Thermoforming Machine

Thermoforming Machine Key Specification Model HEY01-6040 HEY01-7860 Max.Forming Area (mm2) 600×400 780×600 Working Station Forming, Cutting, Stacking Applicable ... -

Model: HEY11

Model: HEY11Automatic Disposable Plastic Glass Making Machine Cup Thermoforming Machine

Cup Making Machine Introduction Plastic glass cup making machine is suitable for molding PP, PET, PS, PLA and other plastic sheets to produce various packaging products such as boxes, plates, cups... -

Model: HEY11

Model: HEY11PLA Biodegradable Hydarulic Cup Making Machine HEY11

PLA Biodegradable Hydarulic Cup Making Machine Biodegradable cup making machine Application GTMSMART Cup Making Machine is specifically designed to work with thermoplastic sheets of var... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY06

Model: HEY06Three Stations Negative Pressure Forming Machine HEY06

Three Stations Negative Pressure Forming Machine HEY06 Application This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package container... -

Model: HEY110B

Model: HEY110BAutomatic Paper Cup Forming Machine HEY110B

Application This paper cup machine mainly for the production of variety of paper cups. Paper Cup Forming Machine Technical Parameter Paper Cup Size 3-16 OZ Sheet Thickness (mm) 0.2-1.5 Raw M... -

Model: HEY03

Model: HEY03Single Station Automatic Thermoforming machine HEY03

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model:

Model:Disposable Plastic Lunch Box Cup Food Container Manufacturer Supplier

Product Details Product Name Disposable Plastic Lunch Box Cup Food Container Material PET, PS, PLA, PP, PVC ect. Custom Order Accept Usage Food packaging, beverages, juice, drink, milk, yo...