Featured

01

Hot-selling Pp 3 Stations Thermoforming Machine - PLC Pressure Thermoforming Machine With Three Stations HEY01 - GTMSMART

2016-01-08

Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc. Feature Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy. Pressure And/Or Vacuum forming. Thermoforming Machine: Upper and down mould forming. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate. Upper & lower heater, four sections heating. Heater with intellectual temperature control system,which has high precision, uniform temperature, won’t be effected by outer voltage.Low power consumption (energy saving 15%), ensure the longer service life of heating furnace. Forming and cutting unit mold open and close controlled by servo motor, products automatically count. Products be stacked downward. Plastic Thermoforming Machine: data memorization function. Feeding width can be synchronously or independently adjusted in electrical way. Heater will automatically push-out when the sheet is over. Auto roll sheet loading, reduce the working load. Plastic Thermoforming Machine Key Specification Model HEY01-6040 HEY01-6850 HEY01-7561 Max.Forming Area (mm2) 600x400 680x500 750x610 3 Stations Forming, Cutting, Stacking Sheet Width (mm) 350-720 Sheet Thickness (mm) 0.2-1.5 Max. Dia. Of Sheet Roll (mm) 800 Forming Mould Stroke(mm) Upper Mould 150, Down Mould 150 Power Consumption 60-70KW/H Forming Mould Width (mm) 350-680 Max. Formed Depth (mm) 100 Cutting Mould Stroke(mm) Upper Mould 150,Down Mould 150 Max. Cutting Area (mm2) 600x400 680x500 750x610 Cutting Force (ton) 40 Dry Speed (cycle/min) Max 30 Product Cooling Method By Water Cooling Vacuum Pump UniverstarXD100 Power Supply 3 phase 4 line 380V50Hz Max. Heating Power 121.6 Max. Power of Whole Machine (kw) 150 Max. Machine Dimension(L*W*H) (mm) 11150×2300×2700 Weight of Whole Machine ( T ) ≈11 Brand of Main Components PLC Taiwan Delta Touch Screen Monitor (10 inch) Taiwan Delta Feeding Servo Motor (3kw) Taiwan Delta Forming Down Mould Servo Motor (3kw) Taiwan Delta Forming Upper Mould Servo Motor (3kw) Taiwan Delta Cutting Down Mould Servo Motor (3Kw) Taiwan Delta Cutting Upper Mould Servo Motor (5.5Kw) Taiwan Delta Stacking Servo Motor(1.5Kw) Taiwan Delta Heater (192 pcs) TRIMBLE AC Contactor French Schneider Thermo Relay Schneider Intermediate Relay Japan Omron Air Switch South Korea LS Pneumatic Component MAC. AirTAC/ ZHICHENG Cylinder China ZHICHENG 20 years experience GTMSMART Machinery Co., Ltd. is an innovative technology enterprise integrating technology, industry and trade. It mainly develops and produces various types of high-precision automatic production equipment. The newly developed GTM series of fully automatic air pressing molding production line includes: feeding unit, pre-heating unit, forming unit, vertical blanking unit, stack unit, scrap winding unit, punching cutting and stacking three-in-one horizontal blanking unit, online labeling unit, etc., which can be combined with flexible production line according to different production requirements of customers.

view

detail

01

Lowest Price for Auto Plastic Vacuum Forming Machine - Four Stations Large PP Plastic Thermoforming Machine HEY02 - GTMSMART

2016-01-08

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high efficiency, suitable for producing plastic trays, containers, boxes, lids, etc. Feature 1.PP Plastic Thermoforming Machine: High degree of automation, production speed. By installing the mold to produce different products, to achieve more purposes of one machine. 2.Integration of mechanical and electrical, PLC control, high precision feeding by frequency conversion motor. 3.PP Thermoforming Machine Imported famous brand electrical components, pneumatic components, stable operation, reliable quality, long using life. 4.The thermoforming machines has compact structure, air pressure, forming, cutting, cooling, blow out finished product feature set in one module, make the product process short, high finished product level, accord with national health standards. Key Specification Model GTM 52 4Station Maximum forming area 625x453mm Minimum forming area 250x200mm Maximum mold size 650x478mm Maximum mold weight 250kg Height over sheet material forming part 120mm Height under sheet material forming part 120mm Dry cycle speed 35 cycles/min Maximum film width 710mm Operating pressure 6 bar

view

detail

01

Newly Arrival Paper Plate And Glass Making Machine Price - 130-180 OZ Paper Bucket Making Machine HEY100-220 - GTMSMART

2016-01-08

Features 1.Paper bucket machine with double turning plate, better for collecting the finished cup. 2.Ultrasonic sealing station for the cup side welding. 3.Two stations Hot air station for the bottom sealing 4.You can make cups of different size by changing molds. 5.Paper bucket making machine with PLC control, touch screen operation 6.Open cam system fully lubrication system in the machine. 7.Low operating cost, 1 worker can handle 1 machine. Paper Bucket Forming Machine Technical Parameter Model HEY100-200 Paper cup size 130-180oz or customize Speed 25~~30 pcs/min Max top diameter 220mm Max bottom diameter 180mm Min top diameter 120mm Min.height 100mm Min bottom diameter 90mm Raw material 250~~380gsm, single or double PE coated paper General power 15KW Air consumption 0.5m³/min Electricity 380V 3 phases Weight 4500kg Outline size (LxWxH) 3.98m×2.1m×1.9m

view

detail

01

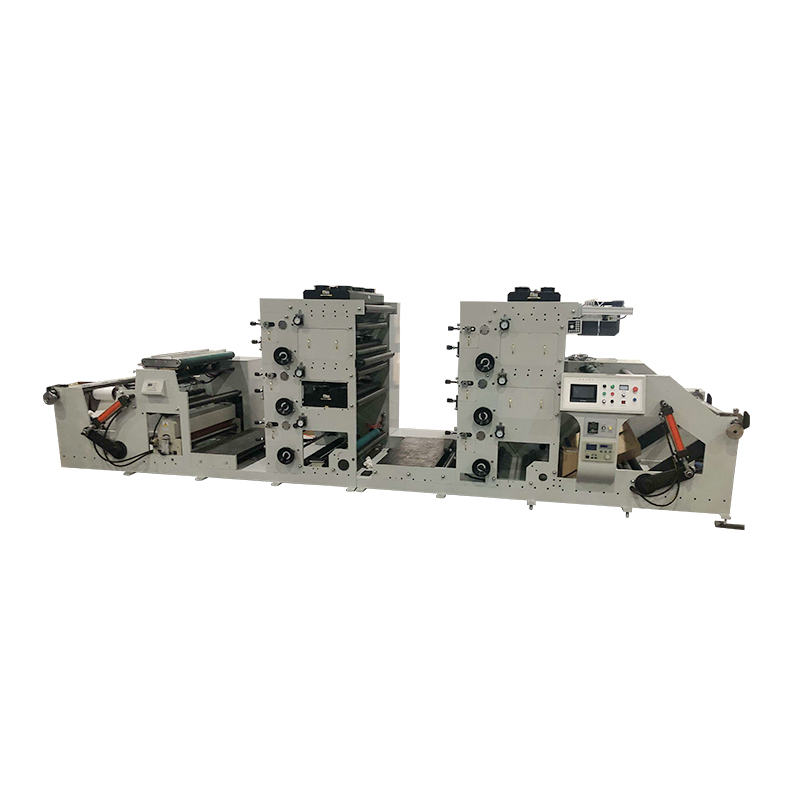

China Factory for Disposable Dish Making Machine - 6 Color Flexo Printing Machine HEY130-6-860 - GTMSMART

2016-01-08

Technical Parameter Printing speed 55m-60m/min Printing color 6 colors Print max width 850mm Unwind roll width 860mm Unwind roll diameter 1300mm Rewind roll max diameter 1300mm Printing length 175-380mm Registering accuracy ±0.15mm Voltage 380V±10% Total power 50kw Air press 0.6MP Oil system Manual Weight 6000kg Dimension 6800mmX2100mmX2050mm Adjust speed motor 90W Main motor 4.0KW Frequency conversion motor 7.5KW Magnetic clutch 200N Huaguang Magnetic break 50N Huaguang Rewind automatic tension control Chuying Unwind automatic tension control Zhongxing Frequency converter 4.0kw Schneider Frequency Converter 7.5KW Schneider Accessories Standard accessories 6pcs Gear motor 6pcs IR dry 1set Rewind unwind hydraulic system 1set AC contactor 1set Button 6pcs Temp control 6pcs Doctor blade 6pcs Ink fountain 1set Tool box 6pcs Bottom mat

view

detail

01

Chinese wholesale Thermoformer With Cup Stacker - Four Stations Large PP Plastic Thermoforming Machine HEY02 - GTMSMART

2016-01-08

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high efficiency, suitable for producing plastic trays, containers, boxes, lids, etc. Feature 1.PP Plastic Thermoforming Machine: High degree of automation, production speed. By installing the mold to produce different products, to achieve more purposes of one machine. 2.Integration of mechanical and electrical, PLC control, high precision feeding by frequency conversion motor. 3.PP Thermoforming Machine Imported famous brand electrical components, pneumatic components, stable operation, reliable quality, long using life. 4.The thermoforming machines has compact structure, air pressure, forming, cutting, cooling, blow out finished product feature set in one module, make the product process short, high finished product level, accord with national health standards. Key Specification Model GTM 52 4Station Maximum forming area 625x453mm Minimum forming area 250x200mm Maximum mold size 650x478mm Maximum mold weight 250kg Height over sheet material forming part 120mm Height under sheet material forming part 120mm Dry cycle speed 35 cycles/min Maximum film width 710mm Operating pressure 6 bar

view

detail

01

Good quality Patal Banane Ki Machine Price - 4 Color Flexo Printing and Cutting Machine HEY150-480 - GTMSMART

2016-01-08

Technical Parameter Printing speed 50m-60/min Printing color 4 colors Max printing width 480mm Feeding width 490mm Max unwinding diameter 600mm Max winding diameter 600mm Max printing area 320x380mm Overprint precision ±0.15mm Voltage 380V±10% Total power Approx.25kw Air pressure 0.6MP Lubrication system manpower Weight 2700kg Dimension 2800mmX1300mmX2250mm Standard Configuration Main Part Main Motor 2.2KW (Shanghai) Magnetic powder brake 50N (homebred) Magnetic powder brake 50N (homebred) Automatic tension control (nakahoshi) Frequency converter 2.2KW (Schneider) Oven fan (homebred) Button (Schneider/Delixi) Waste collecting device Tectorial membrane device Mold cutting device Rectifying device Delivery device Standard Accessories Standard 4 pcs Anilox rollers 4 pcs Printing rollers 4 pcs Scrapers 4 pcs Ink cartridge 1set Tool cabinet 12pcs Base mat

view

detail

01

China OEM Pepper Plete Machine - High Speed PLA Paper Cup Machine HEY110C - GTMSMART

2016-01-08

Application High speed paper cup machine can be used for tea, coffee, milk, ice cream, juice and water. Technical Parameter Paper Cup Size RANGE 2 ~~12OZ Speed 90~~120pc/min Paper cup top diameter in 45mm ~~Max 104mm Paper cup bottom diameter Min 35mm~~Max 75mm Paper cup height Min 35mm~~Max 115mm Raw material 180~~350gsm,single or double PE coating paper and PLA coated paper General power 11 Kw Electricity 380V 3 phases Air consumption 0.2 cbm/min Weight 3000 kg Electrical Configuration Inverter Schneider, France Relay Idec and Omron, Japan Switch Schneider, France PLC system SIEMENS, Japan Touch screen SIEMENS, Japan CONTACTORS Schneider, France

view

detail

01

Special Price for Thermoforming Machine Suppliers - Single Station Automatic Thermoforming machine HEY03 - GTMSMART

2016-01-08

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc. Feature ● More efficient energy use and material utilization. ● The heating station uses high-efficiency ceramic heating elements. ● The upper and lower tables of the forming station are equipped with independent servo drives. ● Single Station Automatic Thermoforming machine has a pre-blowing function to make the product molding more in place. Key Specification Model HEY03-6040 HEY03-6850 HEY03-7561 Max.Forming Area (mm2) 600x400 680x500 750x610 Sheet Width (mm) 350-720 Sheet Thickness (mm) 0.2-1.5 Max. Dia. Of Sheet Roll (mm) 800 Forming Mould Stroke(mm) Upper Mould 150, Down Mould 150 Power Consumption 60-70KW/H Forming Mould Width (mm) 350-680 Max. Formed Depth (mm) 100 Dry Speed (cycle/min) Max 30 Product Cooling Method By Water Cooling Vacuum Pump UniverstarXD100 Power Supply 3 phase 4 line 380V50Hz Max. Heating Power 121.6

view

detail

01

2022 wholesale price Thermoforming Machine Price - PLC Pressure Thermoforming Machine With Three Stations HEY01 - GTMSMART

2016-01-08

Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc. Feature Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy. Pressure And/Or Vacuum forming. Thermoforming Machine: Upper and down mould forming. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate. Upper & lower heater, four sections heating. Heater with intellectual temperature control system,which has high precision, uniform temperature, won’t be effected by outer voltage.Low power consumption (energy saving 15%), ensure the longer service life of heating furnace. Forming and cutting unit mold open and close controlled by servo motor, products automatically count. Products be stacked downward. Plastic Thermoforming Machine: data memorization function. Feeding width can be synchronously or independently adjusted in electrical way. Heater will automatically push-out when the sheet is over. Auto roll sheet loading, reduce the working load. Plastic Thermoforming Machine Key Specification Model HEY01-6040 HEY01-6850 HEY01-7561 Max.Forming Area (mm2) 600x400 680x500 750x610 3 Stations Forming, Cutting, Stacking Sheet Width (mm) 350-720 Sheet Thickness (mm) 0.2-1.5 Max. Dia. Of Sheet Roll (mm) 800 Forming Mould Stroke(mm) Upper Mould 150, Down Mould 150 Power Consumption 60-70KW/H Forming Mould Width (mm) 350-680 Max. Formed Depth (mm) 100 Cutting Mould Stroke(mm) Upper Mould 150,Down Mould 150 Max. Cutting Area (mm2) 600x400 680x500 750x610 Cutting Force (ton) 40 Dry Speed (cycle/min) Max 30 Product Cooling Method By Water Cooling Vacuum Pump UniverstarXD100 Power Supply 3 phase 4 line 380V50Hz Max. Heating Power 121.6 Max. Power of Whole Machine (kw) 150 Max. Machine Dimension(L*W*H) (mm) 11150×2300×2700 Weight of Whole Machine ( T ) ≈11 Brand of Main Components PLC Taiwan Delta Touch Screen Monitor (10 inch) Taiwan Delta Feeding Servo Motor (3kw) Taiwan Delta Forming Down Mould Servo Motor (3kw) Taiwan Delta Forming Upper Mould Servo Motor (3kw) Taiwan Delta Cutting Down Mould Servo Motor (3Kw) Taiwan Delta Cutting Upper Mould Servo Motor (5.5Kw) Taiwan Delta Stacking Servo Motor(1.5Kw) Taiwan Delta Heater (192 pcs) TRIMBLE AC Contactor French Schneider Thermo Relay Schneider Intermediate Relay Japan Omron Air Switch South Korea LS Pneumatic Component MAC. AirTAC/ ZHICHENG Cylinder China ZHICHENG 20 years experience GTMSMART Machinery Co., Ltd. is an innovative technology enterprise integrating technology, industry and trade. It mainly develops and produces various types of high-precision automatic production equipment. The newly developed GTM series of fully automatic air pressing molding production line includes: feeding unit, pre-heating unit, forming unit, vertical blanking unit, stack unit, scrap winding unit, punching cutting and stacking three-in-one horizontal blanking unit, online labeling unit, etc., which can be combined with flexible production line according to different production requirements of customers.

view

detail

01

Competitive Price for Thermoforming Machine Manufacturers China - Four Stations Large PP Plastic Thermoforming Machine HEY02 - GTMSMART

2016-01-08

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high efficiency, suitable for producing plastic trays, containers, boxes, lids, etc. Feature 1.PP Plastic Thermoforming Machine: High degree of automation, production speed. By installing the mold to produce different products, to achieve more purposes of one machine. 2.Integration of mechanical and electrical, PLC control, high precision feeding by frequency conversion motor. 3.PP Thermoforming Machine Imported famous brand electrical components, pneumatic components, stable operation, reliable quality, long using life. 4.The thermoforming machines has compact structure, air pressure, forming, cutting, cooling, blow out finished product feature set in one module, make the product process short, high finished product level, accord with national health standards. Key Specification Model GTM 52 4Station Maximum forming area 625x453mm Minimum forming area 250x200mm Maximum mold size 650x478mm Maximum mold weight 250kg Height over sheet material forming part 120mm Height under sheet material forming part 120mm Dry cycle speed 35 cycles/min Maximum film width 710mm Operating pressure 6 bar

view

detail

01

OEM manufacturer Plastic Cup Machine Price - Factory China Disposable Food Container Lunch Box Making Machine Plastic Thermoformer Machine - GTMSMART

2016-01-08

We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Factory China Disposable Food Container Lunch Box Making Machine Plastic Thermoformer Machine, For more data, please send email to us. We're searching forwards the opportunity to assistance you. We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Disposable plastic food container machine, Plastic Lunch Box Making Machine, Plastic thermoformer machine, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers. Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high efficiency, suitable for producing plastic trays, containers, boxes, lids, etc. Feature 1.PP Plastic Thermoforming Machine: High degree of automation, production speed. By installing the mold to produce different products, to achieve more purposes of one machine. 2.Integration of mechanical and electrical, PLC control, high precision feeding by frequency conversion motor. 3.PP Thermoforming Machine Imported famous brand electrical components, pneumatic components, stable operation, reliable quality, long using life. 4.The thermoforming machines has compact structure, air pressure, forming, cutting, cooling, blow out finished product feature set in one module, make the product process short, high finished product level, accord with national health standards. Key Specification Model GTM 52 4Station Maximum forming area 625x453mm Minimum forming area 250x200mm Maximum mold size 650x478mm Maximum mold weight 250kg Height over sheet material forming part 120mm Height under sheet material forming part 120mm Dry cycle speed 35 cycles/min Maximum film width 710mm Operating pressure 6 bar We normally believe that one's character decides products' quality, the details decides products' high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Factory China Disposable Food Container Lunch Box Making Machine Plastic Thermoformer Machine, For more data, please send email to us. We're searching forwards the opportunity to assistance you. Plastic thermoformer machine, Disposable plastic food container machine, Plastic Lunch Box Making Machine, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

view

detail