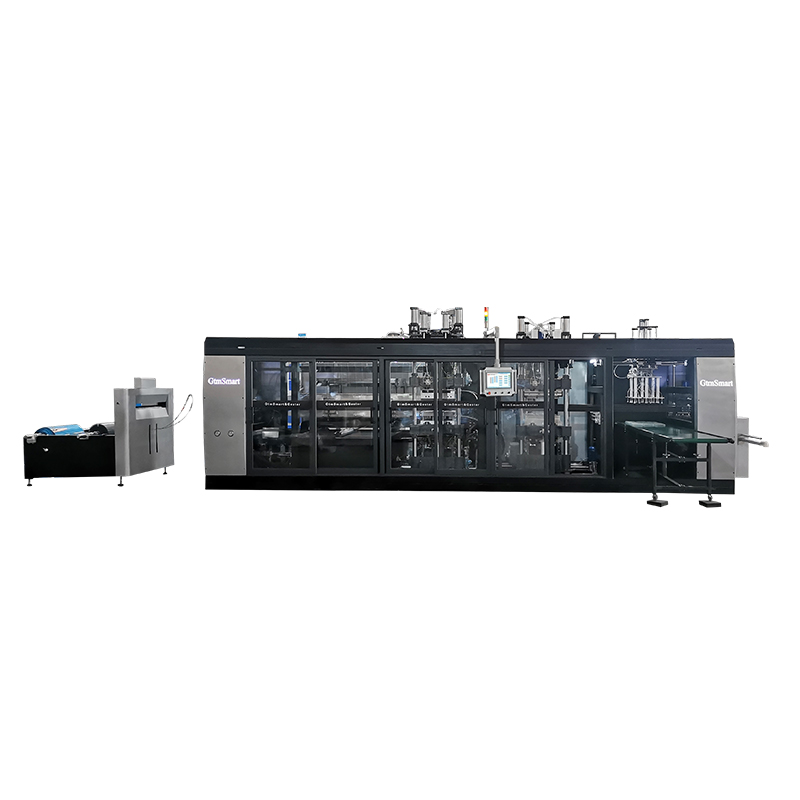

GtmSmart PS/PET/PP/PLA Plastic Thermoforming Machine for Lids Box Tray Fast Food Container

We thinks what clients think, the urgency of urgency to act within the interests of a consumer position of theory, allowing for superior high quality, decreased processing costs, costs are additional reasonable, won the new and old customers the support and affirmation for GtmSmart PS/PET/PP/PLA Plastic Thermoforming Machine for Lids Box Tray Fast Food Container, Our Enterprise Core Principle: The prestige initial ;The standard guarantee ;The customer are supreme.

We thinks what clients think, the urgency of urgency to act within the interests of a consumer position of theory, allowing for superior high quality, decreased processing costs, costs are additional reasonable, won the new and old customers the support and affirmation for Biodegradable Plate Making Machine, Biodegradable Plate Making Machine Cost, Fast Food Box Machine, Plastic Forming Machine For Sale, Plastic Plates Manufacturing Machine, Take Away Box Machine, Termoforming Machine, Thermoforming Plastics Machinery, We’ve been your reliable partner in the international markets of our merchandise. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products and solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

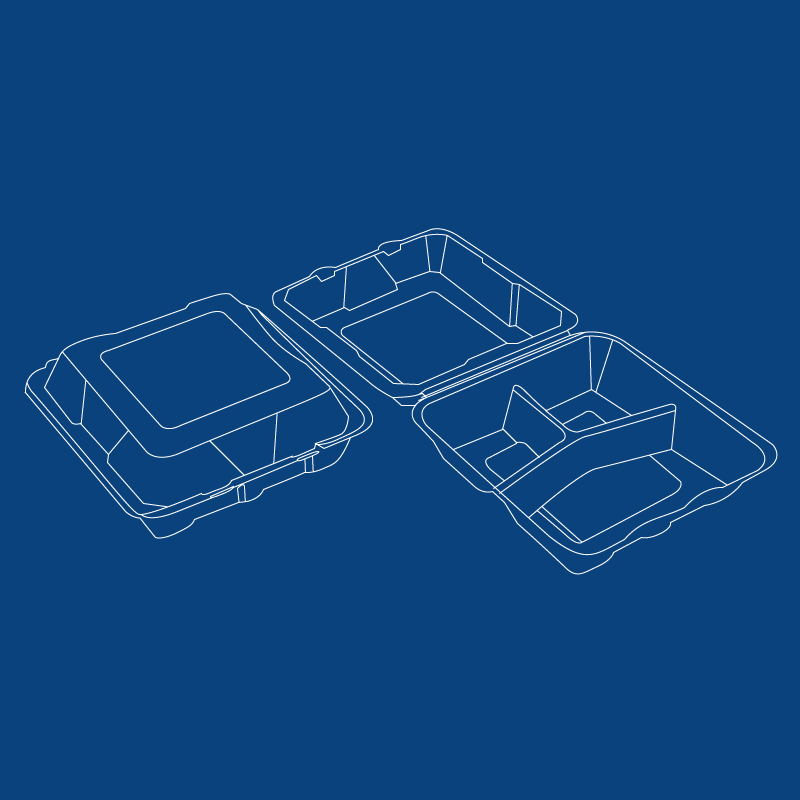

Product Introduction

This Thermoforming Machine Suitable material: PLA, PP, APET, PS, PVC, EPS, OPS, PEEK ect.

Product type: various degradable plastic boxes, containers, bowls, lids, dishes, trays, medicine and other blister packaging products.

Feature

- Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

- Pressure And/Or Vacuum forming.

- Thermoforming Machine: Upper and down mould forming.

- Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

- Upper & lower heater, four sections heating.

- Heater with intellectual temperature control system,which has high precision, uniform temperature, won’t be effected by outer voltage.Low power consumption (energy saving 15%), ensure the longer service life of heating furnace.

- Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

- Products be stacked downward.

- Plastic Thermoforming Machine: data memorization function.

- Feeding width can be synchronously or independently adjusted in electrical way.

- Heater will automatically push-out when the sheet is over.

- Auto roll sheet loading, reduce the working load.

Thermoforming Machine Key Specification

| Model |

HEY01-6040 |

HEY01-7860 |

| Max.Forming Area (mm2) |

600×400 |

780×600 |

| Working Station |

Forming, Cutting, Stacking |

|

| Applicable Material |

PS, PET, HIPS, PP, PLA, etc |

|

| Sheet Width (mm) | 350-810 | |

| Sheet Thickness (mm) | 0.2-1.5 | |

| Max. Dia. Of Sheet Roll (mm) | 800 | |

| Forming Mould Stroke(mm) | 120 for up mold and down mold | |

| Power Consumption | 60-70KW/H | |

| Max. Formed Depth (mm) | 100 | |

| Cutting Mould Stroke(mm) | 120 for up mold and down mold | |

| Max. Cutting Area (mm2) |

600×400 |

780×600 |

| Max. Mold Closing Force (T) | 50 | |

| Speed (cycle/min) | Max 30 | |

| Max. Capcity of Vacuum Pump | 200 m³/h | |

| Cooling System | Water Cooling | |

| Power Supply | 380V 50Hz 3 phase 4 wire | |

| Max. Heating Power (kw) | 140 | |

| Max. Power of Whole Machine (kw) | 160 | |

| Machine Dimension(mm) | 9000*2200*2690 | |

| Sheet Carrier Dimension(mm) | 2100*1800*1550 | |

| Weight of Whole Machine (T) | 12.5 | |

Brand of Main Components

| PLC | DELTA |

| Touch Screen | MCGS |

| Servo Motor | DELTA |

| Asynchronous Motor | CHEEMING |

| Frequency Converter | DELIXI |

| Transducer | OMDHON |

| Heating Brick | TRIMBLE |

| AC Contactor | CHNT |

| Thermo Relay | CHNT |

| Intermediate Relay | CHNT |

| Solid-state Relay | CHNT |

| Solenoid Valve | AirTAC |

| Air Switch | CHNT |

| Air Cylinder | AirTAC |

| Pressure Regulating Valve | AirTAC |

Why Choose Us – Advantages of using PLA biodegradable containers after plastic ban

- GTMSMART one-stop PLA product solution

- PLA biodegradable food container customization

- PLA-an environmentally friendly and degradable new material recognized by the world

- Eco-friendly and biodegradable

- Anti-grease is not easy to penetrate

- Practical

- Strong temperature resistance

We thinks what clients think, the urgency of urgency to act within the interests of a consumer position of theory, allowing for superior high quality, decreased processing costs, costs are additional reasonable, won the new and old customers the support and affirmation for GtmSmart PS/PET/PP/PLA Plastic Thermoforming Machine for Lids Box Tray Fast Food Container, Our Enterprise Core Principle: The prestige initial ;The standard guarantee ;The customer are supreme.

fast food box machine, plastic plates manufacturing machine, termoforming machine, take away box machine, thermoforming plastics machinery, biodegradable plate making machine, plastic forming machine for sale, biodegradable plate making machine cost, We’ve been your reliable partner in the international markets of our merchandise. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products and solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Send your message to us:

Products Recommended

More +-

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY03

Model: HEY03Single Station Automatic Thermoforming machine HEY03

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model: HEY06

Model: HEY06Three Stations Negative Pressure Forming Machine HEY06

Three Stations Negative Pressure Forming Machine HEY06 Application This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package container... -

Model: HEY12

Model: HEY12Full Servo Plastic Cup Making Machine HEY12

Full Servo Plastic Cup Making Machine cup making machine Application The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers,... -

Model: HEY11

Model: HEY11Hydraulic Servo Plastic Cup Thermoforming Machine HEY11

Hydraulic Servo Plastic Cup Thermoforming Machine HEY11 Cup Thermoforming Machine Application The whole Plastic Cup Thermoforming Machine Mainly for the production of variety plastic containers (... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is...