Peb vam khom lub zog technical force thiab txuas ntxiv tsim cov thev naus laus zis kom ua tau raws li qhov kev thov ntawm Tuam Tshoj Plastic PVC Blister Nqus Tshuab Tshuab, Koj puas tseem tab tom nrhiav rau cov khoom lag luam zoo uas yog raws li koj lub tuam txhab zoo duab thaum nthuav koj cov khoom lag luam? Sim peb cov khoom zoo. Koj qhov kev xaiv yuav ua pov thawj tias ntse!

Peb nyob ntawm qhov ruaj khov technical force thiab txuas ntxiv tsim cov thev naus laus zis kom ua tau raws li qhov xav tau ntawmlub tshuab nqus tsev vacuum forming tshuab,Yas tshuab nqus tsev forming tshuab,pvc lub tshuab nqus tsev sib sau tshuab, Nrog lub zog muaj zog thiab txhim khu kev qha ntau dua, peb tau nyob ntawm no los pab peb cov neeg siv khoom los ntawm kev muab cov kev pabcuam zoo tshaj plaws thiab kev pabcuam, thiab peb ua tsaug rau koj txoj kev txhawb nqa. Peb yuav sim ua kom peb lub koob npe nrov ua tus muag khoom zoo tshaj plaws hauv ntiaj teb. Yog tias koj muaj lus nug lossis lus nug, koj yuav tsum hu rau peb dawb.

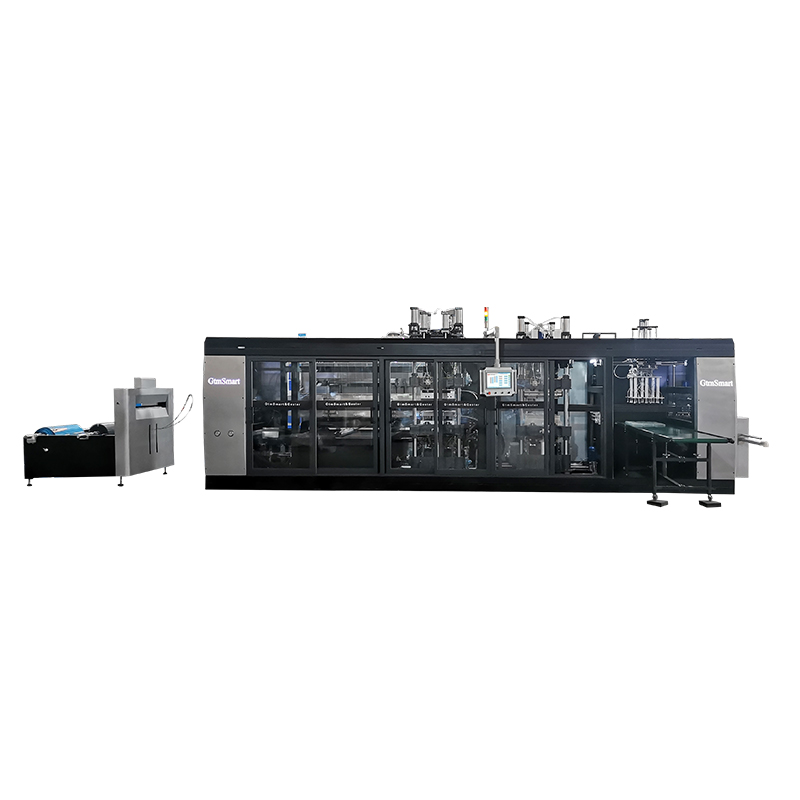

Thermoplastic Vacuum Forming Machine Description

Lub tshuab nqus tsev tsim, tseem hu ua thermoforming, lub tshuab nqus tsev siab los yog lub tshuab nqus tsev molding, yog ib txoj kev uas cov ntawv ntawm cov khoom siv yas rhuab zoo li ib txoj hauv kev.

PLC Tsis Siv Neeg Yas Nqus Tshuab Ua Tshuab: R & D los ntawm peb thiab siv rau kev tsim cov yas thiab ntim khoom, tuaj yeem ua cov khoom yas rau hauv cov duab.

Khoom Zoo

- Qhov noLub tshuab nqus tsev sib sau tshuabtxais PLC tswj qhov system, servo-tsav sab sauv thiab qis pwm discs, thiab servo zaj duab xis pub mis yog ruaj khov thiab raug.

- Lub high-txhais industrial kov screen yog tso tawm kom pom raws li ib tug txiv neej-tshuab interface, thiab tag nrho cov parameter nqis yog saib xyuas ntawm kov screen.

- CovYas tshuab nqus tsev forming tshuabmuaj qhov ua txhaum kev kuaj mob, lub sijhawm ua haujlwm ntawm cov ntaub ntawv tsis raug, yooj yim rau kev khiav lag luam thiab tswj.

- Lub tshuab nqus tsev pvc lub tshuab nqus tsev tuaj yeem khaws ntau yam khoom lag luam, thiab kev debugging yog ceev thaum tsim cov khoom sib txawv.

Tsis Siv Neeg Lub Tshuab Nqus Tsev Tshuab Specifications

| Qauv | HEHEHE 05B |

| Chaw Ua Haujlwm | Kev tsim, stacking |

| Khoom siv tau | PS, PET, PVC, ABS |

| Max. Lub cheeb tsam (mm2) | 1350 * 760 hli |

| Mhauv. Lub cheeb tsam (mm2) | 700 * 460 hli |

| Max. Qhov tob (mm) | 130 |

| Ntawv dav (mm) | 490-790 Ib |

| Daim ntawvThickness(mm) | 0.2 ~ 1.2 hli |

| Qhov tseeb ntawmShu uaTQhov siab (mm) | 0.15 |

| Max.Ua haujlwmCycle(cycles/feeb) | 30 |

| Stroke ntawmINpper/qis Mqub (mm) | 350 |

| Ntev ntawmINpper/qis Hnoj (mm) | 1500 |

| Max. Capacity ntawmVacuumPceev (m3/h) | 200 |

| Hwj chimSupply | 380V / 50Hz 3 kab lus 4 Hlau |

| Qhov Loj (mm) | 4160 * 1800 * 2945 hli |

| Qhov hnyav(T) | 4 |

| Lub zog cua sov(kws) | 86 |

| Lub zog ntawm lub tshuab nqus tsev twj(kws) | 4.5 |

| Lub zog ntawmTsav tshebMtus sau (kws) | 4.5 |

| Lub zog ntawmDaim ntawvMtus sau (kws) | 4.5 |

| Tag nrhoPtus tswv(kws) | 120 |

Xa koj cov lus rau peb:

Cov khoom pom zoo

Ntau +-

Model: HUV 01

Model: HUV 01Loj Layout 3 Chaw Nres Tsheb Siab Ua Haujlwm Thermoforming Tshuab

Khoom Taw Qhia Tag Nrho Tsis Siv Neeg Thermoforming Tshuab: Kev sib xyaw ua ke cua sov, sib sau, xuas nrig ntaus thiab stacking chaw nres tsheb. Thermoformer siv high-efficiency ceramic cua sov ntsiab lus; laser riam pwm, ... -

Model: HUV 01

Model: HUV 01Nruab nrab Layout 3 Chaw nres tsheb PP PET PS PVC Yas Thermoforming Tshuab

Khoom Taw Qhia Qhov Kev Kub Ceev Tsis Siv Neeg Siab PET Thermoforming Tshuab txais cov txheej txheem ntawm laminating cua sov, txais kev siv tshuab ntawm kev txav zaj duab xis xuas nrig ntaus, tsis muaj kev ua qias tuaj, hig ... -

Model: HUV 01

Model: HUV 01Peb Qhov Chaw Ua Haujlwm Tsis Siv Neeg Yas Thermoforming Tshuab

Khoom Taw Qhia Tag Nrho Tsis Siv Neeg Thermoforming Tshuab: Kev sib xyaw ua ke cua sov, sib sau, xuas nrig ntaus thiab stacking chaw nres tsheb. Thermoformer siv high-efficiency ceramic cua sov ntsiab lus; laser riam... -

Model: HUV 01

Model: HUV 01Kev kub ceev tsis siv neeg siab PET Thermoforming Tshuab

Khoom Taw Qhia Qhov Kev Kub Ceev Tsis Siv Neeg Siab PET Thermoforming Tshuab txais cov txheej txheem ntawm laminating cua sov, txais kev siv tshuab ntawm kev txav zaj duab xis xuas nrig ntaus, tsis muaj kev ua qias tuaj, hig ... -

Qauv: HEY02

Qauv: HEY02Plaub Qhov Chaw Loj PP Yas Thermoforming Tshuab HEY02

Cov Khoom Taw Qhia Plaub Qhov Loj Yas Thermoforming Tshuab Feem ntau yog tsim los ntawm ntau yam ntim yas (qe tais, ntim txiv hmab txiv ntoo, ntim khoom noj, ntim ntim, ...