x

Manufactur standard Paper Cup Machine Low Price - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART

Model:

We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Disposable Food Container Suppliers, Thermoforming Machine Em Portugues, Patta Plate Machine Price, Being a young growing company, we might not the best, but we are trying our best to be your good partner.

Manufactur standard Paper Cup Machine Low Price - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART Detail:

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Manufactur standard Paper Cup Machine Low Price - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART , The product will supply to all over the world, such as: Anguilla, Rotterdam, The Swiss, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Manufactur standard Paper Cup Machine Low Price - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART Detail:

cup making machine Application

The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, PET, PE, PS, HIPS, PLA,etc.

Cup Making Machine Technical Specifications

| Model |

HEY12-6835 |

HEY12-7542 |

HEY12-8556 |

| Forming Area |

680*350mm |

750*420 mm |

850*560 mm |

| Sheet Width |

<680 mm |

<750 mm |

<850 mm |

| Max. Forming Depth |

<180 mm |

<220 mm |

<180 mm |

| Heating Rated Power |

130kw |

140kw |

150kw |

| Dimension |

5200*2000*2800mm |

5400*2000*2800mm |

5500*2000*2800mm |

| Machine Total Weight |

7T |

8T |

9T |

| Applicable Raw Material | PP,PS,PET,HIPS,PE,PLA | ||

| Sheet Thickness | 0.2-3.0 mm | ||

| Work Frequency | <35 | ||

| Motor Power | 15kw | ||

| Power Supply | Single Phase 220V or Three Phase 380V/50HZ | ||

| Pressure Supply | 0.6-0.8 Mpa | ||

| Max.air Consumption | 3.8 | ||

| Water Consumption | 20M3/h | ||

| Control System | Siemens | ||

Supply Sheet Rack

| Feeding Reducer with Motor | Worm Gear Reducer (Supror) |

| Pneumatic Pressure | AirTAC Cylinder SC63×25=2PSC |

| Pneumatic Feeding Sheet | AirTAC Cylinder SC100×150=2PSC |

Electric Control

| Human-computer Interface | Siemens |

| PLC | Siemens |

| Servo Stretching Motor | Siemens 11KW servo driver+servo motor |

| Servo Folding Motor | Siemens 15KW servo driver+servo motor |

| Main Reducer | America FALK |

| Feeding Sheet Motor | Siemens 4.4KW servo driver+servo motor |

| Temperature Controller | Japan Fuji |

Forming Station

- Standard square tube frame with 100*100, mould is casted steel and upper mould is fixed by nut.

- Opening and closing mould driven by eccentric gear connecting rod.Driving power by 15KW (Japan Yaskawa) servo motor, American KALK Reducer,main axis use HRB bearings.

- Plastic Cup Thermoforming Machine Main pneumatic component use SMC(Japan) magnetic.

- Sheet feeding device with planetary gear reducer motor, 4.4KW Siemens servo controller.

- Stretching device uses 11KW Siemens servo.

- Lubrication device is fully automatic.

- Caterpillars adopt fully enclosed structure, with cooling device and can manually adjust sheet width.

- Heating system uses China ceramic far-infrared heaters, stainless steel upper and down heating furnace, upper heater with 12 pcs heating pads vertically and 8 pcs heating pads horizontally , down heater with 11 pcs heating pads vertically and 8 pcs heating pads horizontally.(specification of heating pad is 85mm*245mm);Electric furnace push-out system uses 0.55KW worm gear reducer and ball screw, which is more stable and also protect the heater pads.

- Cup Thermoforming Machine Air filtration uses triplet, blowing cup can adjust airflow.

- Folding mould is consist of fixed upper plate、flexible mid plate and 4 pillars with surface hard chrome plating 45#.

- Eccentric is the construction of connecting rod fold mould, with running range ≤ 240mm.

- Electric heating furnace could be moved horizontally and vertically freely by guide-rail from Hiwin Taiwan.

- Toping cups is controlled by AirTAC (Taiwan) cylinder.

Waste Edge Winding Device

- On-line winding

- Reducer with 0.75KW motor (1 pc)

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Manufactur standard Paper Cup Machine Low Price - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART , The product will supply to all over the world, such as: Anguilla, Rotterdam, The Swiss, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

By Griselda from Iraq - 2018.09.23 18:44

By Griselda from Iraq - 2018.09.23 18:44

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

By Rebecca from Slovak Republic - 2018.03.03 13:09

By Rebecca from Slovak Republic - 2018.03.03 13:09

By Griselda from Iraq - 2018.09.23 18:44

By Griselda from Iraq - 2018.09.23 18:44

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

By Rebecca from Slovak Republic - 2018.03.03 13:09

By Rebecca from Slovak Republic - 2018.03.03 13:09

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model:

Model:Reasonable price Plastic Lid Thermoforming Machines - Three Stations Negative Pressure Forming M...

Application Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets. Vacuum Forming ... -

Model:

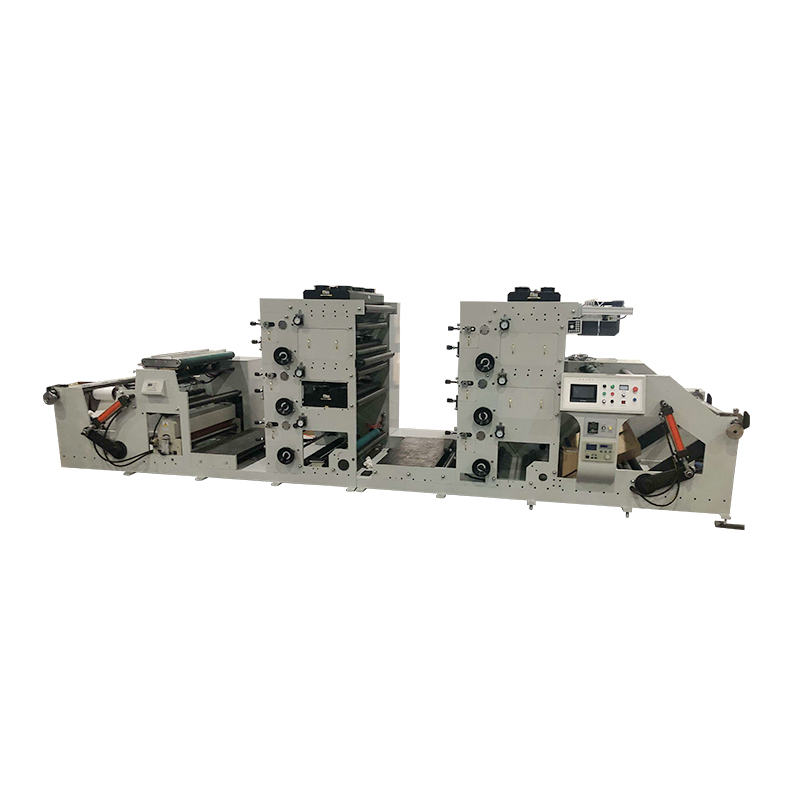

Model:Online Exporter Biodegradable Paper Plate Making Machine - 6 Color Flexo Printing Machine HEY130...

Technical Parameter Printing speed 55m-60m/min Printing color 6 colors Print max width 850mm Unwind roll width 860mm Unwind roll diameter 1300mm Rewind roll max diameter... -

Model:

Good User Reputation for Thermoforming Machine Philippines - Three Stations Negative Pressure Fo...

Application Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets. Vacuum Forming ... -

Model:

Model:Reasonable price Top Thermoforming Machine Manufacturers - Four Stations Large PP Plastic Thermo...

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high eff... -

Model:

Model:Ordinary Discount Food Container Making Machine - Single Station Automatic Thermoforming machine...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model:

Model:Top Quality Disposable Plastic Container Making Machine - Three Stations Negative Pressure Formi...

Application Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets. Vacuum Forming ...