Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. A plastic sheet is heated in an oven then stretched into or onto a mold and cooled to a finished form.

What are the types of plastic thermoforming?

The two main types of thermoforming are vacuum forming and pressure forming.

Vacuum Forming

Vacuum forming uses heat and pressure to shape plastic sheets. First, A sheet is heated and placed over a mold, where a vacuum manipulates it into the desired shape. When the material is detached from the mold, the final result is a precise shape. This type of thermoforming produces dimensionally stable parts on one side with high-quality esthetics on the other material side.

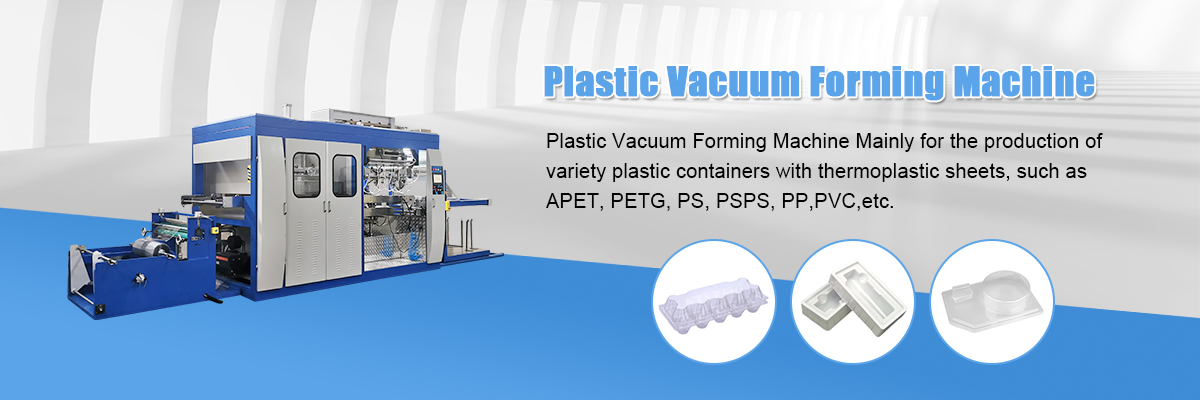

Such as, GtmSmart Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is shaped a certain way.

PLC Automatic Plastic vacuum Forming Machine: Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets, such as APET, PETG, PS, PVC,etc.

Pressure Forming

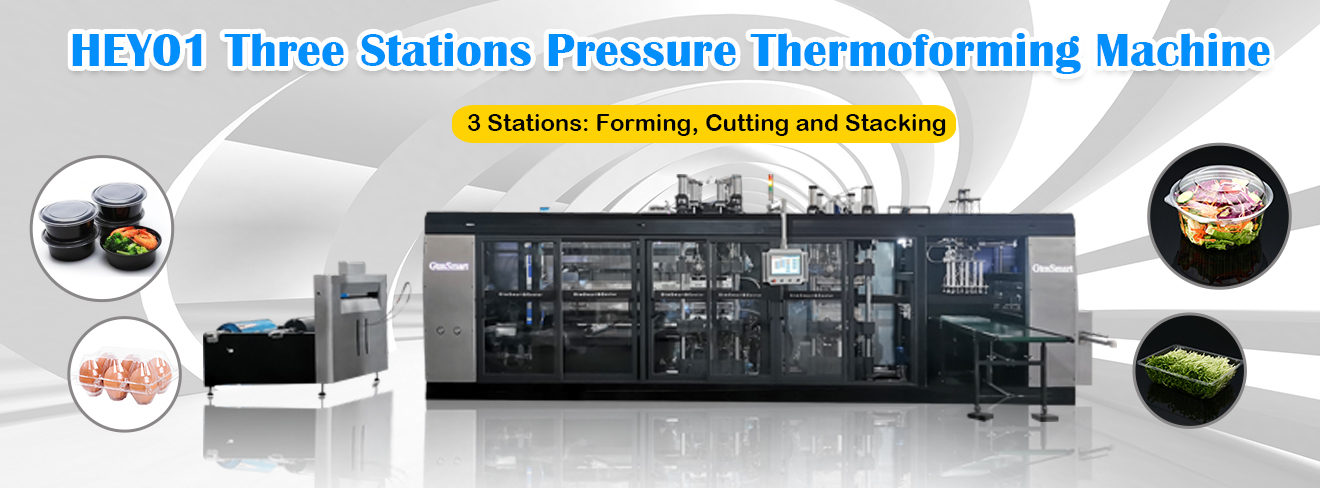

Pressure forming is similar to vacuum forming but benefits from added pressure. The process also involves heating a sheet of plastic and also adds a pressure box to the non-mold side of the sheet. The extra pressure causes sharp detail.

Such as, GtmSmart Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc.

Post time: Jan-05-2023