The Application and Development of Plastic Bowl Making Machine

The Application and Development of Plastic Bowl Making Machine

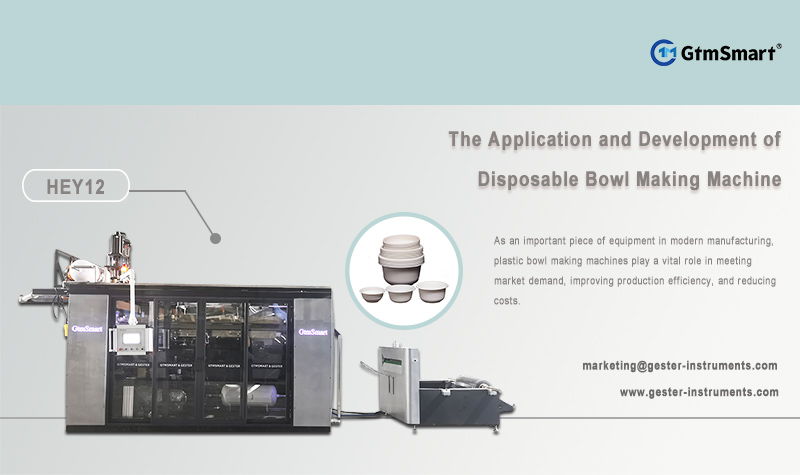

With the development of society and the acceleration of the pace of life, disposable plastic products have been widely used in daily life due to their convenience. As a new type of production equipment, the plastic bowl making machine offers an economical and environmentally friendly solution through efficient production processes and the use of eco-friendly raw materials. This article will delve into the working principle, market demand, environmental benefits, and economic advantages of disposable bowl making machines, analyzing their significant role in modern manufacturing.

1. Working Principle of disposable bowl making machines

Disposable bowl making machines use a thermoforming process, starting with plastic sheets, and producing disposable plastic bowls through steps like heating, forming, and cutting. The main workflow includes the following steps:

-Plastic Sheet Preparation: Using plastic sheets made of polypropylene (PP), polystyrene (PS), and other materials, which are typically produced by specialized manufacturers, ensuring good formability and durability.

-Sheet Heating: The plastic sheets are fed into the heating zone, where infrared heaters or electric heaters heat them to a softened state, making them malleable.

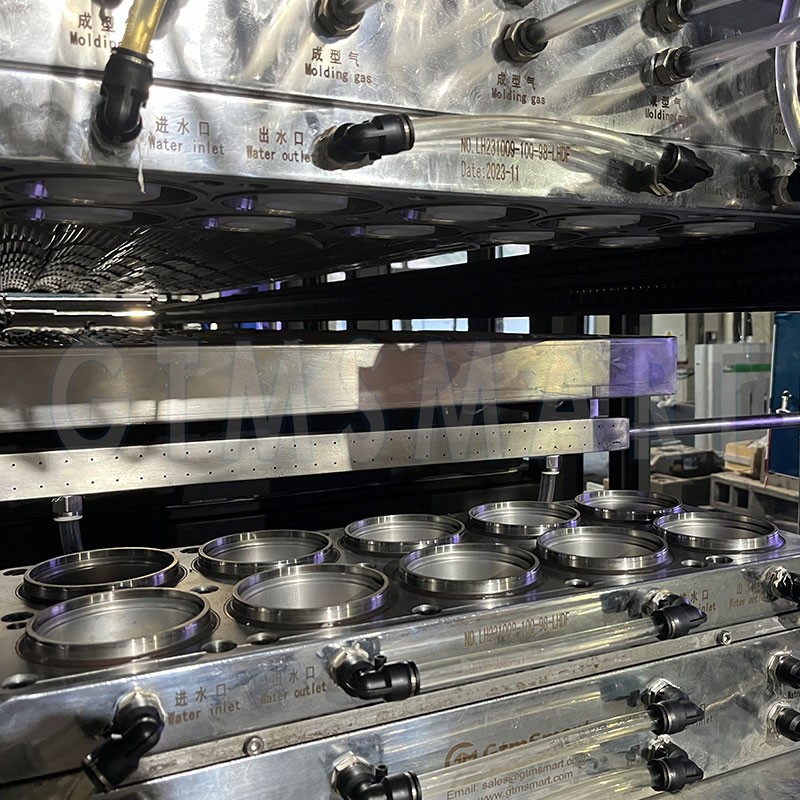

-Forming: The heated sheets are conveyed to the forming molds, where they are stretched and shaped over the mold surface , forming the shape of a bowl.

-Cooling and Setting: The formed bowls are rapidly cooled by cooling devices to ensure they maintain a stable shape.

2. Market Demand and Development Prospects

The demand for disposable plastic bowls is primarily concentrated in the food service, fast-food takeout, and family gatherings. With the booming development of the takeout industry, the demand for disposable plastic bowls continues to grow. The specific market demand analysis is as follows:

-Food Service Industry: Disposable plastic bowls are widely used in fast food restaurants, eateries, and takeout platforms due to their lightweight and ease of use. Especially during large events and holidays, the demand significantly increases.

-Household Use: In occasions such as family gatherings, picnics, and travel, disposable plastic bowls are favored by consumers for their convenience and hygiene.

-Special Applications: In places with high hygiene requirements like hospitals and schools, disposable plastic bowls are frequently used to ensure single-use and reduce the risk of cross-infection.

3. Environmental Benefits Analysis

Through technological innovation and proper management, the environmental benefits of disposable plastic bowls can be significantly improved:

-Application of Degradable Materials: With technological advancements, more degradable plastic materials are being developed and applied in the production of disposable products. These materials degrade faster after use, reducing environmental impact.

-Recycling and Reuse: Establishing a comprehensive recycling system to improve the recycling rate of disposable plastic bowls and reduce resource waste. Through recycling and reuse, old plastic products can be processed into new plastic sheets, enabling resource circulation.

-Green Production Technology: Adopting energy-saving and environmentally friendly production technologies and equipment, such as energy-efficient heaters and automated control systems, to reduce energy consumption and waste emissions during production.

4. Economic Benefits Analysis

Plastic bowl making machines have significant advantages in terms of economic benefits:

-High Production Efficiency: Compared to traditional injection molding processes, the thermoforming process has a shorter production cycle and higher efficiency, making it suitable for mass production and reducing the production cost per unit product.

-Cost Control: The cost of plastic sheets is relatively stable, and with the high automation level of thermoforming machines, labor costs are significantly reduced, leading to overall controllable production costs.

-Robust Market Demand: With the rapid development of the takeout and fast-food industries and consumers' pursuit of convenient lifestyles, the market demand for disposable plastic bowls continues to grow, providing businesses with vast market opportunities.

Additionally, through technological upgrades and product innovations, companies can develop higher value-added products, such as plastic bowls with better heat and cold resistance, to meet the needs of different consumers and application scenarios, further enhancing market competitiveness and economic benefits.

As an important piece of equipment in modern manufacturing, plastic bowl making machines play a vital role in meeting market demand, improving production efficiency, and reducing costs. Companies need to continuously innovate, promote degradable materials and green production technologies, and establish a comprehensive recycling system to achieve a balance and unity between economic and environmental benefits. Through joint efforts, we can enjoy modern conveniences while protecting our planet and achieving the goal of sustainable development.