What are the Differences Between Vacuum Forming, Thermoforming, and Pressure Forming?

Thermoforming is a manufacturing process in which a sheet of plastic is heated into a flexible shape, which is then shaped or formed using a mold, and then trimmed to make a final part or product. Both vacuum forming and pressure forming are different types of thermoforming processes. The main difference between pressure forming and vacuum forming is the number of molds that are used.

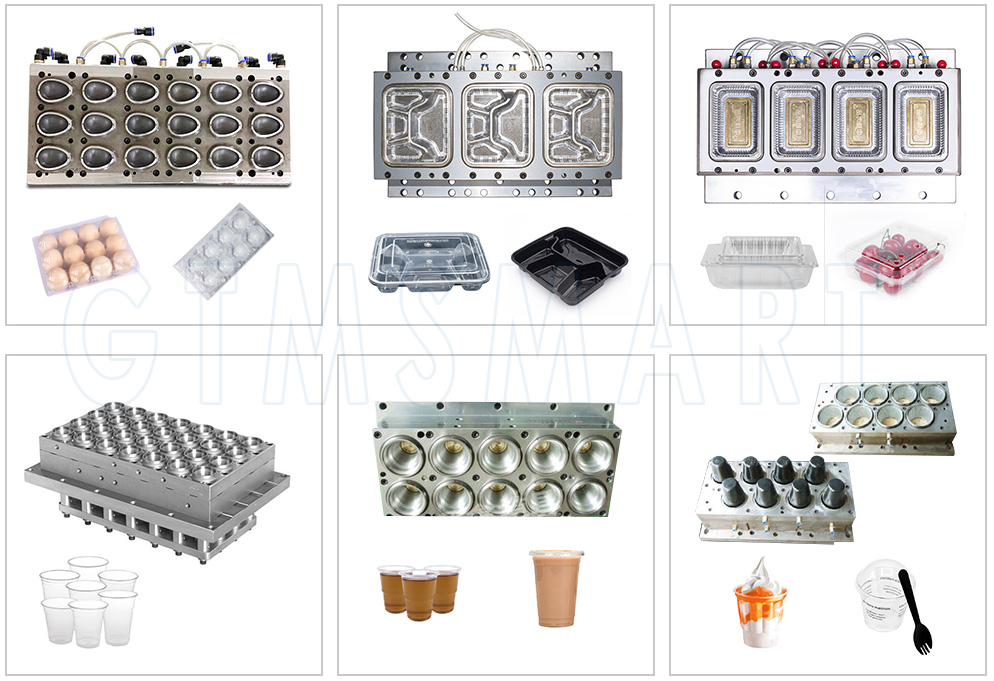

Vacuum forming is the simplest type of plastic thermoforming and uses a mold and vacuum pressure to achieve the desired part geometry. It is ideal for parts that only need to be precisely shaped on one side, such as contoured packaging for food or electronics.

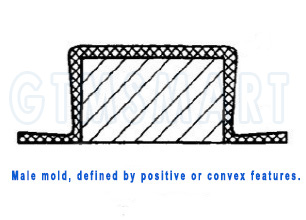

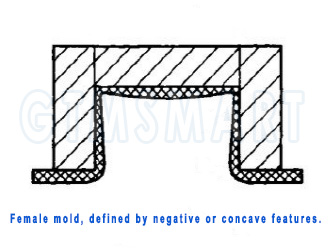

There are two basic types of molds—male or positive (which are convex) and female or negative, which are concave. For male molds, a plastic sheet is placed on the mold to form an outline of the internal dimensions of the plastic part. For female molds, thermoplastic sheets are placed inside the mold to precisely form the outer dimensions of the part.

In pressure forming, a heated plastic sheet is pressed between two molds (hence the name), rather than being pulled around a single mold by suction. Pressure forming is ideal for manufacturing plastic parts or pieces that need to be more precisely shaped on both sides and/or require a deeper draw (they need to extend farther/deeper into a mold), such as appliance casings that need to look aesthetically pleasing on the exterior and snap into place or fit a precise size on the interior side.

Post time: Feb-28-2022