x

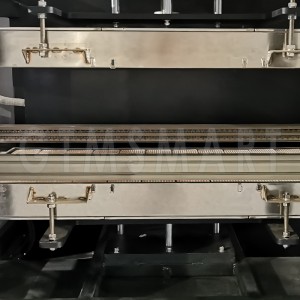

Cylinder Plastic Vacuum Ho Etsa Mochini HEY05A

Litlhaloso tsa Mochini oa Vacuum Form

| Mohlala | HEY05A |

| Setsi sa Mosebetsi | Ho theha, Stacking |

| Boitsebiso bo sebetsang | PS, PET, PVC, ABS |

| Max. Sebaka sa ho theha (mm2) | 1350*760 |

| Min. Sebaka sa ho theha (mm2) | 700*460 |

| Max. Botebo bo entsoeng (mm) | 130 |

| Bophara ba Leqephe (mm) | 490-790 |

| Botenya ba Leqephe (mm) | 0.2 ~ 1.2 |

| Ho Nepaha ha Sepalangoang sa Leqephe (mm) | 0.15 |

| Max. Mosebetsi oa potoloho (lipotoloho/metsotso) | 30 |

| Stroke of Mold e ka Holimo/Ka Tlase (mm) | 250 |

| Bolelele ba Heatere e ka Holimo/ka Tlase (mm) | 1500 |

| Max. Bokhoni ba Pump ea Vacuum (m3/h) | 200 |

| Phepelo ea motlakase | 380V/50Hz 3 Polelo ea 4 Mohala |

| Boholo (mm) | 4160*1800*2945 |

| Boima (T) | 4 |

| Matla a ho futhumatsa (kw) | 86 |

| Matla a Pump ea Vacuum (kw) | 4.5 |

| Matla a Sheet Motor (kw) | 4.5 |

| Kakaretso ea Matla(kw) | 100 |

MOSEBETSI OA LIKELETSO

| PLC | DELTA | |

| Skrine se thetsoang | MCGS | |

| Servo Motor | DELTA | |

| Asynchronous Motor | CHEMEKE | |

| Mofetoleli oa khafetsa | DELIXI | |

| Transducer | OMDHON | |

| Setene se futhumatsang | TS'ELISO | |

| AC Contactor | CHNT | |

| Relay ea Thermo | CHNT | |

| Relay ea Mahareng | CHNT | |

| Relay ea naha e tiileng | CHNT | |

| Valve ea Solenoid | AirTAC | |

| Phetoho ea Moea | CHNT | |

| Air Cylinder | AirTAC | |

| Valve e Laolang Khatello | AirTAC | |

| Tlosa Pompo | BAOTN | |

Ke Hobane'ng ha U Re Khetha

- Ho kopanya likarolo tse tsoetseng pele le ts'ebetso e phahameng, mochini ona oa morao-rao o u lumella ho etsa lihlahisoa tsa boleng bo holimo habonolo ho tsoa ho lisebelisoa tse fapaneng tse kenyelletsang.PS, PET, PVC le ABS.

- Ka mechini ea rona ea vacuum thermoforming, o ka fihlela ts'ebetso e nepahetseng le ts'ebetso e nepahetseng molemong oa ho theha le ho bokella.Mochini oa ho etsa li-vacuum tsa Plastiki o na le moaho o tšoarellang o netefatsang ts'ebetso e tšoarellang nako e telele le ho ts'epahala.Hore na o khoebo e nyane kapa moetsi e moholo, mochini ona o loketse bokhoni bohle ba tlhahiso.

- E 'ngoe ea melemo ea mantlha ea mechini ea vacuum thermoforming ke ho ikamahanya le maemo. E na le lisebelisoaka software e tsoetseng pele e ka fetoloang habonolo le ho lokisoa bakeng sa boholo le libopeho tse fapaneng tsa sehlahisoa.Ho feto-fetoha ha maemo ho u thusa ho fihlela litlhoko tse fetohang tsa 'maraka.

- Ho sebetsa mochini oa Vacuum Form ho monate haholobonolo le mosebedisi-ba botsoalle . Sebaka sa taolo se hlakileng se netefatsa ho tsamaea le ts'ebetso e bonolo, ho fokotsa sekhahla sa ho ithuta bakeng sa opareitara. Ho feta moo, mochine o na le liphetoho tse potlakileng tsa lefu ho fokotsa nako ea ho fokotsa nako le ho eketsa tlhahiso. Sena se bolela tlhahiso e ngata ka nako e nyane, ho eketsa phaello ea khoebo ea hau.

- Re utloisisa bohlokoa ba ts'ehetso e ntle ea bareki, ke ka lebaka leo sehlopha sa rona sa litsebi tse hloahloa se lulang se le teng ho thusa le ho tšehetsa ha ho hlokahala.Ho tloha ho ho kenya ho ea ho tlhokomelo le ho rarolla mathata, re ikemiselitse ho netefatsa ts'ebetso ea hau e sa sitisoeng le khotsofalo ka kakaretso.

Lisebelisoa

Re romelle molaetsa oa hau:

Ngola molaetsa wa hao mona mme o re romele wona

Lihlahisoa tse khothalelitsoeng

Tse ling +-

Mohlala: HEY05B

Mohlala: HEY05BMochini oa ho Etsa Setsi sa Servo Vacuum HEY05B

Litlhaloso tsa Mochini o Ikemetseng oa Vacuum oa ho Etsa Moetso oa HEY05B oa Seteishene sa Ts'ebetso sa ho Etsa, ho Lokisetsa lisebelisoa tse sebetsang PS, PET, PVC, ABS Max. Sebaka sa ho Etsa (mm2) 1350 * 760 Min. Formi... -

Mohlala: HEY01

Mohlala: HEY01Mochini oa Thermoforming oa Plastiki oa PLA o ka senyehang oa Lebokose la Plate Bowl

Thermoforming Machine Key Specification Model HEY01-6040 HEY01-7860 Max.Forming Area (mm2) 600×400 780×600 Working Station Forma, Cutting, Stacking Applicable Mater... -

Mohlala: HEY11

Mohlala: HEY11Mochini oa Thermoforming oa Mohope oa Mohope o Lahloang ka Othomathike

Kenyelletso ea Mochini oa ho Etsa Mohope oa Mochine oa ho etsa likhalase tsa polasetiki o loketse ho bopa PP, PET, PS, PLA le maqephe a mang a polasetiki ho hlahisa lihlahisoa tse fapaneng tsa ho paka joalo ka mabokose, lipoleiti, linoelo ... -

Mohlala: HEY11

Mohlala: HEY11PLA Biodegradable Hydarulic Cup Ho Etsa Mochini HEY11

PLA Biodegradable Hydarulic Cup Mochini oa ho Etsa Mochini oa ho etsa Mohope o ka khonang, Mochini oa ho etsa Mohope oa GTMSMART o etselitsoe ka ho khetheha ho sebetsa ka maqephe a thermoplastic a mater... -

Mohlala: HEY02

Mohlala: HEY02Liteishene tse 'ne Mochini o Moholo oa PP oa Plastic Thermoforming HEY02

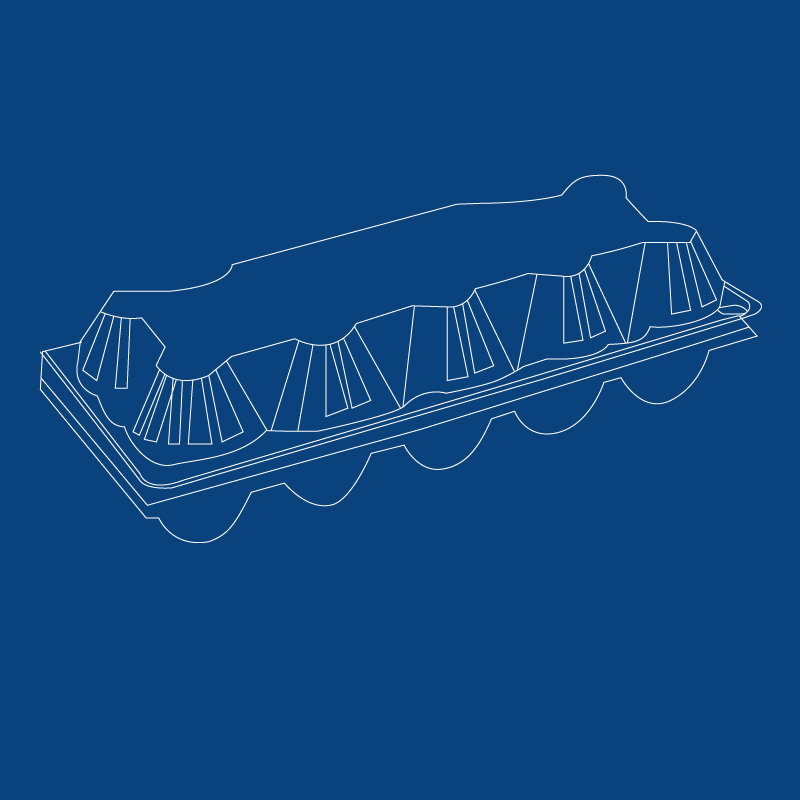

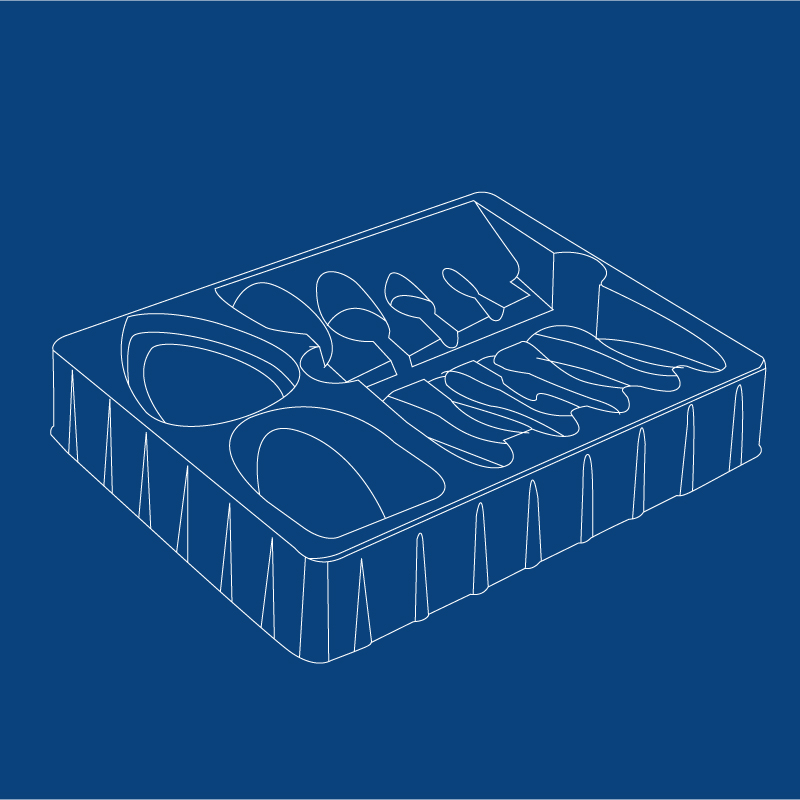

Selelekela sa Sehlahisoa Mechini e Mene e Meholo ea Thermoforming ea Plastiki Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (terei ea mahe, sejana sa litholoana, setshelo sa lijo, lijana tsa liphutheloana, jj)... -

Mohlala: HEY06

Mohlala: HEY06Liteishene tse Tharo Mochini o Etsang Khatello e Ntle HEY06

Sets'oants'o sa Mechini e Tharo e Negative Pressure e Etsang Mochini oa HEY06 Mochini ona oa Thermoforming Haholo-holo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (tray ea mahe, setshelo sa litholoana, setshelo sa sephutheloana... -

Mohlala: HEY110B

Mohlala: HEY110BMochini o Iketsetsang oa Mohope oa Ho Etsa Mohope HEY110B

Kopo Mochini ona oa senoelo sa pampiri haholo-holo bakeng sa tlhahiso ea mefuta e fapaneng ea linoelo tsa pampiri. Mohope oa Letlapa o Etsang Mochini oa Teknoloji Parameter Mohope oa Boholo 3-16 OZ Botenya ba Lakane (mm) 0.2-1.5 Raw M... -

Mohlala: HEY03

Mohlala: HEY03Mochini o le mong oa Seteishene o Iketselitseng Thermoforming HEY03

Kenyelletso ea Sehlahisoa Mochini o le Mong oa Thermoforming Mochini o Iketselitseng Haholo bakeng sa tlhahiso ea lijana tsa polasetiki tse fapaneng (tray ea mahe, setshelo sa litholoana, setshelo sa lijo, lijana tsa liphutheloana, jj) ka ... -

Mohlala:

Mohlala:Lahiloeng Plastic Lunch Box Cup Mofani oa Lijo tsa Setshelo Mofani

Lintlha tsa Sehlahisoa Lebitso la Sehlahisoa le lahloang la Plastic Lunch Box Mohope oa Sets'oants'o sa Lijo PET, PS, PLA, PP, PVC ect. Taelo e Tloaelehileng Amohela Tšebeliso ea Lijo, lino, lero, seno, lebese, ...